Processing

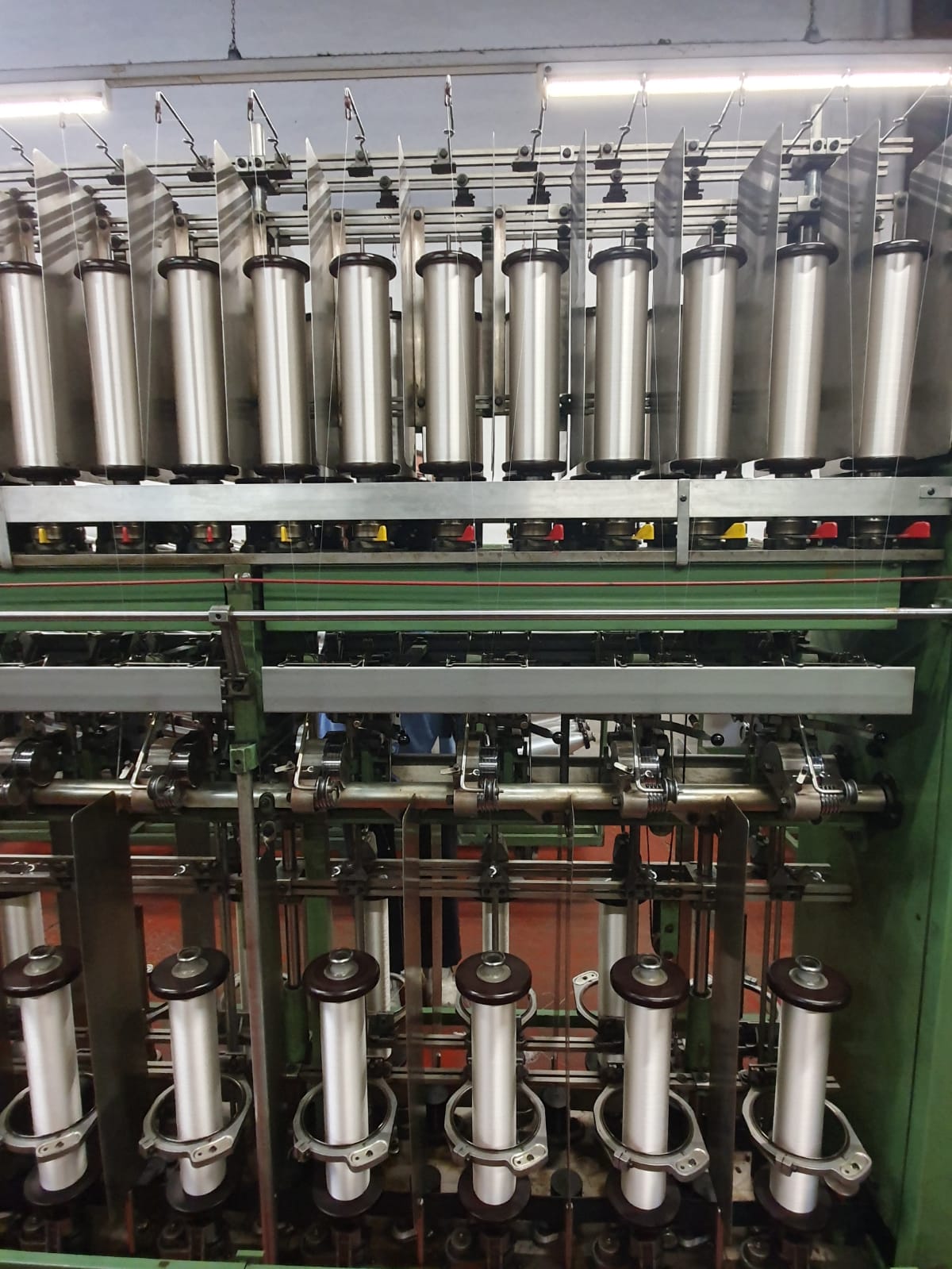

Winding

Our large fleet of machines with diverse equipment for specific processes enables us to supply hard precision-wound cones for fabric or knitwear, yarn balls with optimized unwinding for high speed weaving or soft cones for polyester, nylon and viscose nylon. Currently our machinery can process from 20 to 1800 den numbering for winding or doubling with other threads.

Intermingling

Interlacing is the process that uses compressed air to increase the garment resistance, increase the amount of threads or elasticize with a single or multi-thread elastomer. Interlacing allows us to use our basic made-to-stock products or other components and create a wide range of different goods to be used as warp, weft with a mix of patterns and colors, elastic yarns for knitwear and fabric. We manage to analyze and meet any requirements in the fastest possible time.

Uptwisting

Throwing is a process implemented to change the hand of yarns and their appearance, increase resistance and robustness when they are used for warping or weave that shall comply with parameters of specific methods like Martindale. Based on requirements and needs, we can supply yarns with low throwing or SZ crepe to balance machine weaving.

Twisting

Besides increasing the twist of a single thread, we can provide multi-thread twisting both for similar or different fibers, numbering and colors. Twisting is therefore not only a way to increase yarn thickness or resistance, but also to make creative yarns, finished or raw, to be used with subsequent over-dyeing for a two-color or matte-glossy effects.

Covering

In addition to interlacing and throwing the yarn after interlacing, we can supply spun yarns with elastomer through machines with a specific ironing table, so that the elastic base material is perfectly covered and the typical glossy look of spandex will not come out.

Dyeing

We cooperate with several well-known local dyers to provide a ready-to-ship service for dyed fibers, make lab-dips for color approval and sample dyeing of shades for the most basic to the fluo high-tech colors to meet specific requirements, like for instance the triangular symbol of the UNI EN 471 standard. Each fiber has its own dyer: we cooperate with specialized subcontractors for every different item, so that our - and your - polyester, nylon and rayon fibers, whether it is static or elastic or microfiber, will always be handled by industry experts.